Prarthana

Micro Robots

Introductory class

Day 1

14.09.15

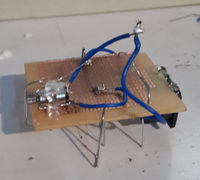

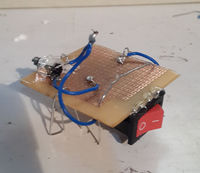

Building my own Robot on the very first day kick- started my interest in electronics. Not only did we learn how to build a basic circuit but also how to solder. Soldering makes your work look much neater and also adds the basic strength required within the different components of a circuit. What boosted my learning was the fact that we did all of this practically with minimal theory. I believe that what you learn practically by experimenting is far more effective and deeper than what you learn merely through theory.

This robot had a simple logic behind it; the battery and the switch were connected to a small motor, whose vibration caused the PCB to move. Something that I wouldn’t have thought of, despite the knowledge about how to make these connections to run a motor. While making the robot one of the major difficulties I faced was when one of the motor legs broke after the entire circuit was soldered onto the PCB. In which case I learned how you could de-solder the excess solder on the leg using a de- soldering pump and solder the wire directly to the metal connection on the motor’s body. The other difficulty that I faced was while making the legs of the robot using U-pins. While making the connections on the PCB and securing them using glue gun and soldering, I didn’t think about the holes through which the legs could pass. Due to which I wasn’t able to attach four legs on four corners which would balance the structure. After experimenting a little I attached three legs to the structure in a triangular manner followed by two pseudo legs on the front to maintain balance.

One thing I think I really need to work on is neatness and securing connections. I believe that my robot, to an extent, is still fragile. Also my soldering tends to get messy, which I would get better at as I practice more.

Trip to SP road

Day 2

15.09.15

It was a very tiring day, but going to this hub of electrical supplies was worth all the physical and mental exhaustion. It was interesting how the entire lane consisted of electrical shops, some big some small. I wondered how the market worked with competition all around you. Why would you place all these electrical stores right next to each other, where you get more or less the same things. But when we went around a couple of stores asking for the list of things we needed, we realized that all these shops had some sort of a healthy tie-up. We went to a couple of stores, where they didn’t have all the materials on the list, instead of asking us to buy whatever they had, they suggested different stores where we would find all the things at one stop. So all of them helped each other out to ensure a collective sale. This was also portrayed when, at Vishaal electronics, they bought the things that they didn’t have, and were on our list, from the neighboring stores.

Buying all the things by going there ourselves was definitely worth experiencing as opposed to if we would have received the list of things sitting here. I got to learn so many different things from observing and just looking around; from how they organize all the supplies in their store to how people working in the store operate to ensure maximum efficiency. Later, counting each and every thing and ticking on the checklist and also negotiating was also an experience in itself. That was the time, when the few of us who survived till late, got mentally exhausted, checking and calculating around 40 different components for around 5 and 11 people who ordered together.

Intro to Components

Battery

Mini Project: Making a lemon battery

A lemon battery has a simple logic behind it; you insert two metals, zinc and copper to it, which would act as positive and negative electrodes as the acidic lemon juice enables the flow of electrons through it. This when attached to an LED, using electrical wires, would supply enough power to enable it to glow. When I tried it in practicality, I started with attaching an LED to one lemon battery. I realized that the voltage produced by one lemon was not enough to light up an LED. Upon experimenting and connecting several lemons together we were finally able to produce the voltage of around 2V. However, when we measured this using a multimeter, it fluctuated a lot. Probably this was the reason behind the LED still not lighting up.

The fact that, despite doing so much, the LED didn’t light up, was disappointing. However, the battery was functional, as measured by the Multimeter. During the process one of the major difficulties faced was finding the materials. Copper wires were easily available, but we needed a source of zinc. We asked around for galvanized nails for the same, but the shopkeepers didn’t have that knowledge themselves (whether the nails that they sold were galvanized). After looking around at all the possible places, we landed up on one of the hardware stores in Yelahanka New Town where they did possess galvanized nails. Overall, the project was accomplished as we did make the battery which was functional, however it wasn’t demonstrated properly by lighting up an LED.

Switch

Making a crazy switch

Resistors

Fixed Resistors

Variable Resistors

Potentiometer

Thermistor

LDR

Capacitors

Diodes

Transistors

Transistor touch switch

555 oscillator

making oscillator, changing inputs